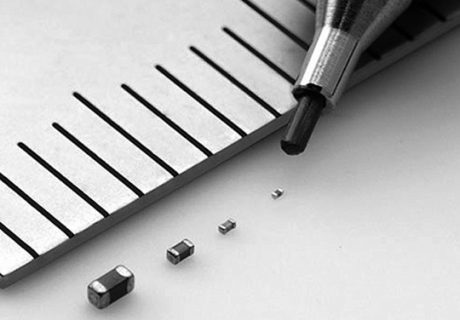

At the end of last month, Murata to invest $354m in new plant as iPhones drive parts demand. The global supply of the capacitors is tightening, due in part to increased usage in electric vehicles and the release of new iPhones. Observers say the rising demand may squeeze electronics manufacturers.

Overall demand for electronics components is expected to grow as countries roll out fifth-generation mobile networks and more electric vehicles hit the road. Murata has already raised prices on all of its capacitors to help offset capital spending.

These days several Japanese passive component manufacturers have announced investments to expand production. Following Murata and Kyocera, another manufacturer has reported news of expansion today.

According to Japanese media reports, Mitsui Chemicals’ subsidiary Mitsui Chemicals Tohcello plans to build a new release film factory for MLCC due to the rapid expansion of demand for automotive MLCC and the surge in demand for related materials. Construction of the plant is expected to start in 2019, with the goal of doubling the production capacity of MLCC release film before the end of 2025.

According to the report, the annual global production of automobiles is nearly 100 million units. With the electronicization of vehicles, it is estimated that the number of MLCCs carried by each vehicle will be increased from the current maximum of 6,000 to 10,000. At present, Mitsui Chemicals Tohcello’s factory for producing release film for MLCC is mainly located in Ibaraki, Japan. On the site of the new plant, Mitsui Chemicals Tohcello may consider setting up a plant in Japan, and will consider other Asian regions as well as China.