How to realize the digital and intelligent transformation of the electronic industry chain from hardware design, component delivery, and manufacturing is a problem faced by new digital supply chain service providers.

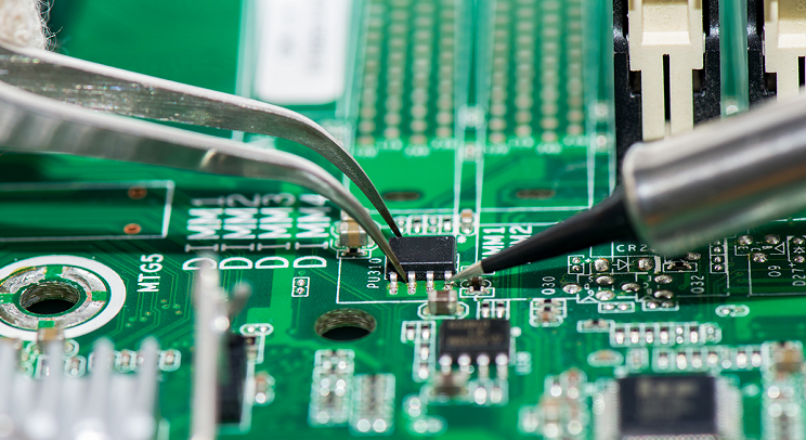

Customers in different industries have diverse needs or requirements for assembling and PCBA production, and traditional self-operated factories cannot meet all the requirements. In the hardware industry, there will be increasing demand and higher requirement on productivity. In addition, flexible production is also required during the entire process.

The essence of flexible production is the ability to quickly respond to various changes according to the needs of the manufacturing industry. It can realize the rapid reconfiguration of the manufacturing system and the optimal allocation of resources to meet the production needs of fragmented orders. As a new digitalized supply chain service provider, Allchips integrates a large number of downstream foundries for system coordination to build a digital factory, and connects hundreds of cooperative foundry factories with information such as labels, portraits and real-time production capacity dynamics with Allchips. In the system, downstream hardware companies can quickly stock up according to the BOM in the system, and choose a suitable foundry to place orders to achieve a high degree of coordination in production capacity. In this way, it can not only meet the diversified market demand for assembling and PCBA production and speed up the entire hardware product manufacturing cycle and circulation efficiency, but also provide the operation status of each production line and project of the entire intelligent manufacturing center through the system.

From the overall perspective, the new digitized supply chain is a process of standardization, digitization and intelligentization. Through the creation of a flexible supply chain and production system, Allchips allows the end customers to acquire semi-finished or finished products while only providing a BOM. The allchips system will automatically complete the process from BOM costing, risk assessment and component procurement to PCBA production. The whole process is completed intelligently, which speeds up the entire product manufacturing cycle, improves the production and circulation efficiency of the industry chain as well as reduces costs. Most importantly, it makes sourcing PCBA starting from one piece is possible.

Gu Xuan, a partner of Chengwei Ventures Evergreen Fund, said that

Chengwei Ventures Evergreen Fund has a great number of fruitful investment cases in the Internet industry such as Baibu, Ruiying, and Jifei. When we study a vertical industry, we will first look at the scale, the shape and dynamic changes of the upstream and downstream industry. There will be opportunities for the birth of new unicorns in a large market where the upstream and downstream are changing rapidly. The trend of localization of upstream components in the electronics industry chain and the explosive growth of downstream demand and product category updating has brought a historic new opportunity to the industry. Allchips has a very unique entry point and strong data/technology accumulation in the circulation link. We highly recognize the persistence and deep industry knowledge accumulation of Allchips in the technology-enabled industry. We also believe in Allchips that it can improve the efficiency of supply chain and accelerate the process of localization of components with the employment of technology and data to help many small and medium-sized electronic terminal enterprises in China.

With the rise of Industry 4.0 in Germany, the Industrial Internet in the United States, and the rise of Chinese industry in 2025, the world has entered the era of intelligent computing. The traditional supply chain has started the transformation toward digitalization, internet of things, cloud computing, big data, and artificial intelligence. The rise of a new round of technological revolution is fundamentally undergoing and subverting the original system. The new supply and intelligent production will be the next “opportunity”.