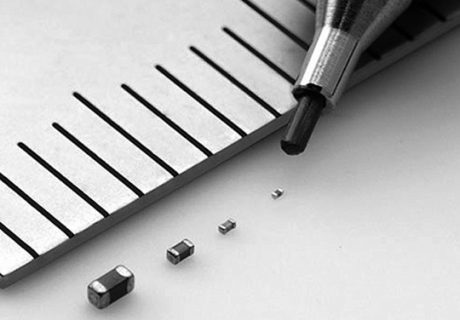

In the past, high value-added products with technological leadership in the MLCC industry will achieve higher profits. Japanese manufacturers are technological pioneers, constantly pursuing higher capacitance, smaller size and more dielectric. For example, Murata, in order to expand its competitive advantage, has successively bought Rohm and Panasonic’s MLCC business unit. Strive to achieve the same value in smaller size to enhance competitive advantage and gross margin.

Why the Shortage of MLCC ?

The shortage of MLCC could be resulted from 3 reasons: Japanese suppliers converting capacity, demand and supply structure changed, and demand increased.

Japanese Suppliers Converting Capacity

Since the 2nd half of 2016, Japanese main suppliers, Murata, Taiyo Yuden, gradually converted their capacity for general-type MLCCs to high-end MLCCs due to the demand from automotive, industry, and iPhone. That is to say, these Japanese suppliers are withdrawing from the general-type MLCC market.

Demand and Supply Structure Changed

It is said that Japanese suppliers and some Taiwan suppliers have been concentrating on niche-type MLCC products to offer the applications in automotive, industry, and high-end smart phone, which can bring higher average selling price (ASP) and profit. However, the major impact would be that it’s challenging for all MLCC suppliers to extend their equipment due to the lead time for MLCC equipment becoming 8 – 12 months.

Increasing Demand

The increasing demand of MLCC also leads to the shortage. The demand from major smart phone suppliers, including Apple, Samsung, and even the Chinese suppliers, like Huawei, Vivo, and Oppo, exceeds the supply. In addition, automotive industry requires large numbers of passive components, especially the popularity of electronics cars and self-driving cars. A car used to require 2000 pieces of passive components, whereas an electronics car may need thousands of pieces.

Although Yageo and Walsin are technically behind Japanese and Korean producers, they have gained more gross margin and market share in the past year due to their standard MLCC capacity advantages, the target applications of these MLCCs, such as computers, consumer electronics, and network communications, have been in high demand in the past year. For example, Yageo’s gross margin is about 60%, surpassing Murata and Samsung, mainly due to the shortage of stocks in the spot market of standard products, driving the contract price to rise.

For MLCC manufacturers, it is very important to regularly expand production capacity, especially for traditional standard products, because traditional products are very sensitive to changes in supply and demand. If there is a slight shortage or inventory changes, the spot market price will soon reacted. However, the MLCC for automobiles is different, because the price of high-end and automotive products is relatively high, the price increase is limited. In addition, the supply of high-end and automotive products is contracted and rarely supplied through the open market or stock market, therefore, stock vendors cannot speculate on the price through the stock market.

Due to the price increase of medium and low-end standard MLCC, the performance and profits of producers such as Yageo and Walsin have soared. At present, manufacturers from Taiwan have dominated the global low-end standard MLCC market. The strategy of Taiwanese Manufacturer is to maintain a slight shortage of market supply while Increasing the proportion of long-term customers to makes the price not easy to fall, the price fluctuation of MLCC will be smaller in the future.

It is worth noting that the next battlefield of MLCC will be the automotive market. Since each car needs more than 80 ECUs, luxury cars need more than 100 ECUs. These control components need to be configured with MLCC.

Taiwan, China MLCC producers intend to enter the automotive market supply chain to avoid the impact of the mid-low-end standard product price plunging. The shortage in the past year is a good opportunity for these producers because it has changed the industrial structure of passive components, resulting in a significant increase in the market share of Taiwan producers in the global MLCC market. Although Taiwan manufacturers are planning late in the automotive market, their next step is to accelerate the development of high-capacity, large-size and automotive products, selectively expand production, and the global supply structure will continue to change.

Related News:

5G will drive the demand for MLCC

The MLCC Production Capacity Will Remain Stable For a Period of Time

Yageo Again Releases MLCC Price Adjustment Notice

Samsung recruits production line employees to meet the rising MLCC demand

The Changes in Industry Trends Behind The MLCC Shortage