YMTC, Innotron (Hefei Chang Xin) and JHICC are scheduled to start trial memory ic production of NAND Flash, mobile DRAM and specialty DRAM, respectively, in the second half of 2018, according to DRAMeXchange. China has taken a big step in its push into the memory IC industry. Three major Chinese companies are getting ready for trial production of DRAMs and NAND flash in the second half of 2018. Mass production will follow in the first half of 2019, marking China’s first domestic chip production.

Equipment was installed at Innotron’s fab in the third quarter (Q3) of 2017, according to DRAMeXchange, but the company has postponed trial production until Q3 2018, which will be followed by mass production in the first half (1H) of 2019.

JHICC, focused on specialty DRAM, also postponed its trial production until Q3 2018 and mass production until 1H 2019. The company announced its plan in July 2016 to invest $5.3 billion in a new 12-inch wafer fab in Jinjiang, Fujian Province.

Both Innotron and JHICC are behind in their announced schedules, DRAMeXchange reported.

Innotron may face other challenges. Industry watchers don’t think Chinese memory IC makers will be able to develop advanced technology without infringing on patents or forming a joint venture partnership.

“Innotron apparently wants to compete head to head with top DRAM suppliers by choosing LPDDR4 8Gb chips as its first product, but there is a strong possibility that Innotron will have potential issues of patent infringement,” said DRAMeXchange. “To avoid arguments, Innotron will need to accrue IPs that are recognized by the international laws. Another safer approach is to sell products only in the domestic market at the outset.”

Samsung’s capex spending levels will put a stop to “any hopes that Chinese companies may have of becoming significant players in the 3D NAND flash or DRAM markets,” and “just about guarantees that without some type of joint venture with a large existing memory suppler, new Chinese memory startups stand little chance of competing on the same level as today’s leading suppliers,” Bill McLean, president of IC Insights, said last year.

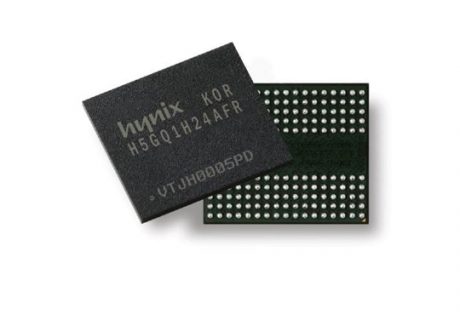

“Even if they were to develop advanced technology on their own, the new Chinese suppliers would almost certainly infringe upon numerous DRAM and NAND patents held by Samsung, SK Hynix, Micron, etc.,” he added.

In the NAND flash segment, YMTC plans to build three 3D-NAND flash manufacturing plants sequentially in three phases. The first-phase was completed in September 2017 with equipment installation scheduled in the third quarter of 2018, followed by trial production in the fourth quarter, said DRAMeXchange. The plant will manufacture 32-layer MLC 3D-NAND Flash. Wafer starts aren’t expected to exceed 10,000 per month.

“The construction of the second- and third-phase plants and their production plans will proceed according to the situation after YMTC perfects its 64-layer design,” said DRAMeXchange.

Supply and demand

DRAMeXchange analysts don’t expect the competitive landscape of the global DRAM market to change in the near term following the entry of JHICC and Innotron. However, analysts believe the Chinese DRAM makers may have fully loaded capacity by 2020/2021 as their products mature, reaching 250,000 wafers per month, which could impact the market by that time frame.

For NAND flash, YMTC’s three facilities will have a total capacity of 300,000 wafers per month. “YMTC may start to significantly raise its wafer starts once it has finished developing its 64-layer products,” said DRAMeXchange. “This ramp-up in turn may have a huge effect on the overall market supply of NAND Flash in the next three to five years.”

Currently, DRAMeXchange is forecasting a slight oversupply in the NAND flash market in the first quarter of 2018, which is expected to continue into the second quarter. At the same time, prices ae expected to fall. SK Hynix reported during its first quarter conference call that average selling prices (ASPs) for NAND flash fell 1 percent compared to the previous quarter.

As a result of oversupply in the market, DRAMeXchange reported that some manufacturers are slowing down their production expansion. “The next-generation 9x-layer NAND flash process will not see sizeable shipment until 2019.”

However, demand is expected to pick-up in the second half of 2018, during the peak season. An increase in average NAND flash content per smartphone also is forecast to drive bit shipment growth in the second half, according to analysts and memory manufacturers.

“Mobile customers are continuing to aim for their better smartphone sales, based on differentiation through higher NAND content with 128 gigabyte NAND being adopted for not only the flagship UFS smartphones but also for mid-end smartphones with eMCP,” said Myung-young Lee, executive vice president and CFO, SK Hynix, during the company’s first quarter conference call this week. “Following this trend there will be continued high adoption of high density 3D NAND for smartphones.”

Memory manufacturers also expect to see an increased share of 64-layer and 72-layer NAND flash, which will increase supply starting in the second quarter and into the second half of the year. However, demand seasonality coupled with increased content per box will result in a supply and demand balance.

“For the NAND market, we believe the ongoing transition to 64-layer 3D NAND creates the opportunity for a more balanced industry dynamic in calendar 2018 versus the constrained conditions we saw in 2017,” said Sanjay Mehrotra, CEO, Micron Technology Inc., during the company’s Q2 earnings call in March.

“We expect industry bit output growth to be somewhat higher than 45% in calendar 2018, providing incremental supply to address the increasing demand created with the further displacement of HDDs in client, enterprise and cloud applications.”

These trends will likely result in tight supply in the second half of the year, said DRAMeXchange, and moderate price declines of eMMC/UFS, PC/enterprise SSD and other products.