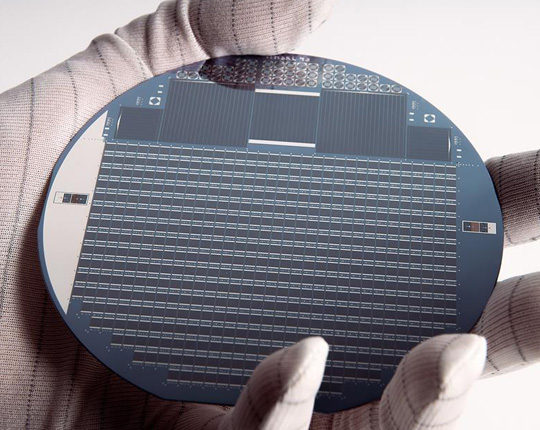

TSMC confirmed that its 8-inch wafer OEM production line capacity is loose.

Previously, many foreign investors have issued reports pointing out that after the loosening demand for 12-inch silicon wafers, the original shortage of 8-inch silicon wafers due to repeated orders resulting in capacity loosening. Recently, TSMC confirmed that the company’s 8-inch wafer OEM line is no longer fully loaded, meaning that the original queuing for capacity faded.

According to industry analysts, 8-inch silicon wafers are mainly used in power management wafers, LCD driver chips, microcontrollers, fingerprint identification chips, and MOSFETs. The reason for TSMC’s overcapacity should be related to the weak sales of smartphones, consumer electronics into the off-season and the weakening of the high-resolution TV boom.

Although TSMC did not explain the reasons for the loosening of capacity, legal persons speculated that the weak sales of smartphones, consumer electronics into the off-season, coupled with the fading high-resolution television boom, resulting in a weakening of smartphone fingerprint identification, panel drive IC and some computer management chip orders.

TSMC’s 8-inch wafer subcontractor has always been the industry’s preferred, with its capacity loosening, corporate worries, the world, Lianhe and other industries are more vulnerable.

Semiconductor manufacturers say 8-inch silicon wafers are widely used in power management chips, panel drive chips, microcontrollers, fingerprint identification chips, metal-oxygen half-field effect transistors (MOSFETs) and other products.

TSMC’s 8-inch wafer foundry has always been the industry leader. As its production capacity status changes, other companies in the industry, such as the world’s advanced (VIS) and UMC, will be even more affected.